Anti-fire door leaf making machine whole line is designed for making the anti-fire door leaf or door panle in batch and automatically.

What is anti-fire door?

Accredited by designated by the Ministry of economic affairs and laboratory of China, we have the new version of the fire door national standard GB GB_12955-2008. And the new standard has been tested and confirmed. After authorization identifier issued by the Bureau of standards, inspection, Ministry of economic affairs "and then we call some understandard door as fire doors. Now this is quite popular all over the world. And in American, the NFPA and IBC specification defines the fire door is "to work together to provide a combination of opening a certain degree of fire protection of any fire doors, door frame, hardware and other accessories.

In the market, there are many type anti-fire door makign machines, but here I only take the steel anti-fire door making machine whole line for example.

Here is the drawing profile and door picture for your referenence:

In the following part, some elements and door making machine parameters for your reference:

Motor decoiler:

Loading ability: 5T Decoiling width: 1200mm

Inner diameter:450-550mm Power: motor expansion

Moter brand: Chinese famous brand |

125 Leveling system:

Machine size: 2300mm width PLC control box one set

Leveling roller: six upper rollers and 7 down rollers. Cutting blade thickness:1300mm

Runout table plate:80x2000mm |

Hydraulic shearing system:

Machine size:3040x1610x1020 with one PLC control box

Machine power: 5.5kw hydraulic shearing

blade:2500 width

Shearing blade:2500mm

Net weight: 4 ton

Supported material thickness: Max 1.5mm |

| Machine pictures for your reference |

|

| Second part: Punching holes and removing endsThere are two sets of punching machine, one is for the upper layer and then second one for another layer. On the anti- fire door, there are those types' holes: lock hole, hinge hole, interlocked holes and others. |

The first one-Door leaf five heads punching machine.

1.PLC control box.

2.Punching working station five.

3.Each hydraulic jack could be moved transversely and lengthwise easily. And using the gear zip method to do the adjustments.

4.Pressing power: 80 Ton.

5.Main power: 11 kw

6.The punching material thickness should be within 1.5mm

7.Hydraulic pump one set. |

The second Door leaf Six heads punching machine:

8.PLC control box.

9.Punching working station six.

10.Each hydraulic jack could be moved transversely and lengthwise easily. And using the gear zip method to do the adjustments.

11.Pressing power: 100 Ton.

12.Main power: 11 kw

13.The punching material thickness should be within 1.5mm

14.Hydraulic pump one set. |

| Machine pictures for your reference |

By those punching machines, you can adjust the hole size, hole distance and others according to your requirements. |

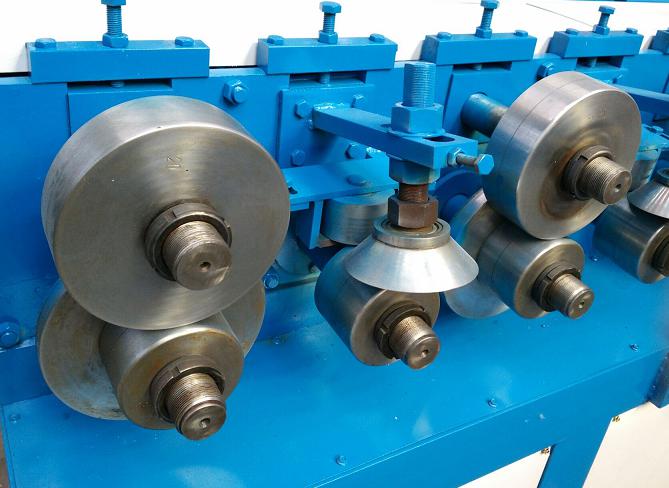

Third part- main roll forming machines to change the angle

Now we got the specified length and width metal plate, we need to change it to the door shape and make two plate could be interlocked easily. |

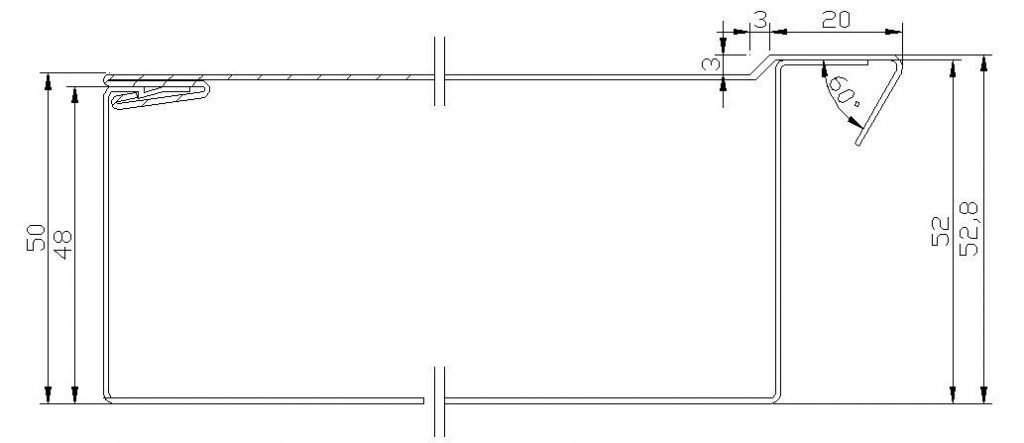

|

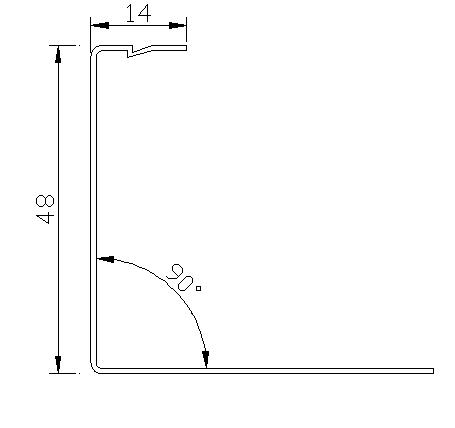

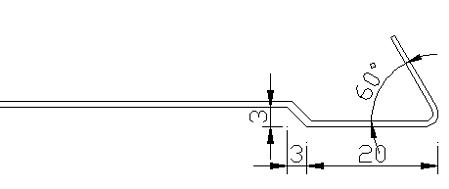

Detail drawing profiles of each angle:

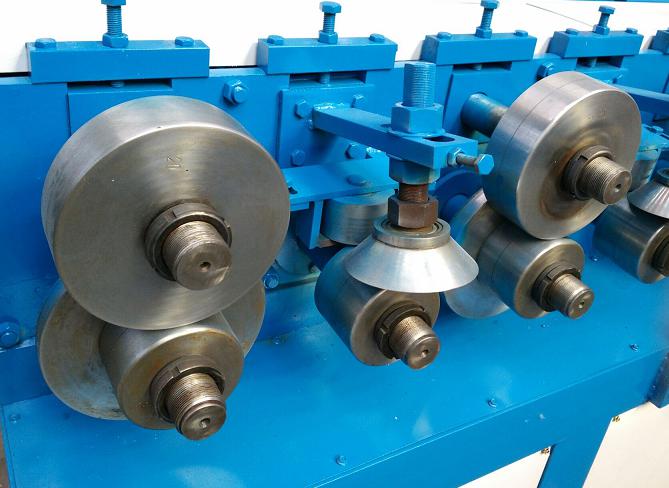

Main roll forming machine for this angle:

1.Main size 3 meter long.

2.14 roller stations

3.Main machine motor:4kw

4.Reduction box

5.Roller shaft diameter: 48mm

6.Roller material: GCR15 steel Chromium plating

7.Supported material thickness:0.8mm

8.6209 type gear. |

|

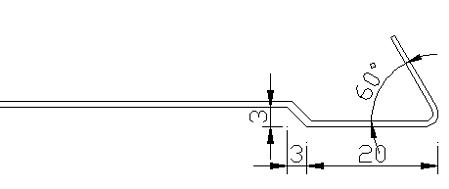

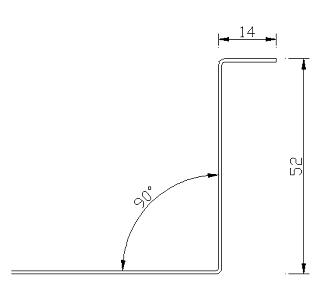

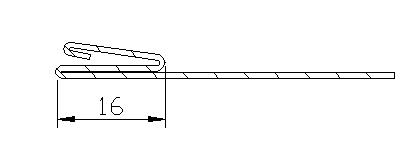

Main machine for the following drawing:

|

Main parameters of machine:

1.Machine size: 4 meter

2.16 roller station.

3.Reduction box: 250 type

4.Main machine shaft: 48mm

5.Roller material: GCR15 steel Chromium plating

6.Supported material thickness:0.8mm

7.6209 type gear. |

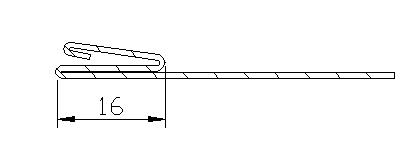

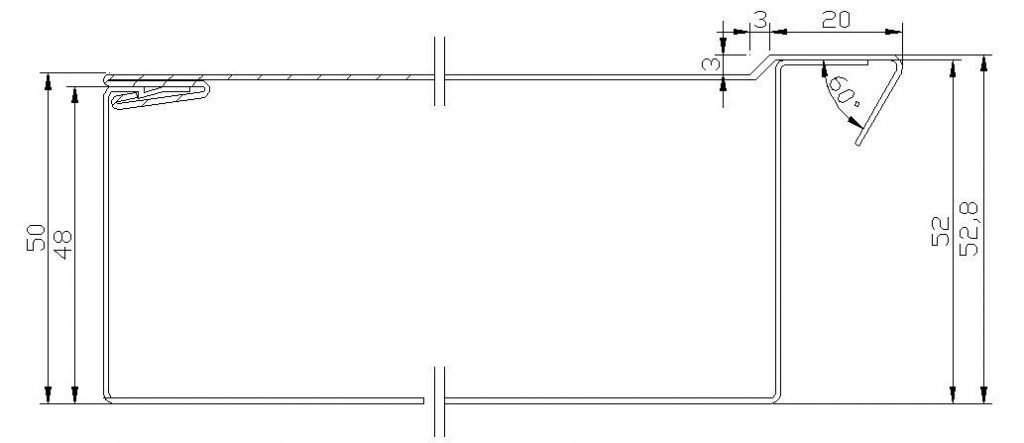

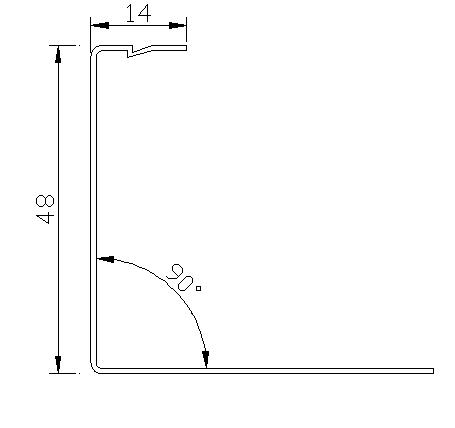

Main machine for the following drawing:

Main parameters:

1.Machine size: 6 meter

2.20 roller station.

3.Two motors of main machine, the Motor power is 4kw/set

4.Reduction box two sets: 250 type

5.Main machine shaft: 48mm

6.Roller material: GCR15 steel Chromium plating

7.Supported material thickness:0.8mm

6209 type gear. |

|

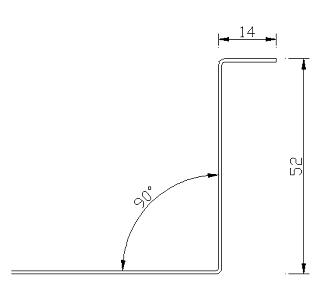

Main machine for the following drawing:

Main parameters:

8.Machine size: 6 meter

9.20 roller station.

10.Two motors of main machine, the Motor power is 4kw/set

11.Reduction box two sets: 250 type

12.Main machine shaft: 48mm

13.Roller material: GCR15 steel Chromium plating

14.Supported material thickness:0.8mm

6209 type gear. |

|

Fourth parts Pressing Roll gluing machine for make perfect shape

This part can help you make the shape of door more beautiful. By pressing and roll forming principle.

Main parameters for your reference:

1.Machine size: 9 meter long

2.Rubber roller moving up and down supporting framing system.

3.Rubber roller driving system.

4.The door edge triming machine

5.Door leaf adjustable width system and servo sizing motor system.

6.Heating system: totally seven pairs 14 heating roller station

7.Door panel conveying system.

8.PLC control system.

9.There are totally 31 pairs of rubber roller stattion, totally 62 rubber rollers |

| Machine pictures for your reference: |

|

Here is the anti-fire door working video for your reference:

For this machine, if you have any problem, please contact me at any time.