Fully automatic Cee, Zee Purline Rolling forming Machine could be used to make the Cee purline and Zee pulrine in batch and fully automatic. The purlins produced by Purlin Roll Forming Machine are widely used in the main body stress structure of the large and medium-size construction, such as the plant, the warehouse, locomotive shed, hangar, exhibition building.

Normally speaking, the C & Z purline thickness could be range from 1.5 to 3.5mm with punching holed. Based on the market needs, we design two in one fully automatic production.

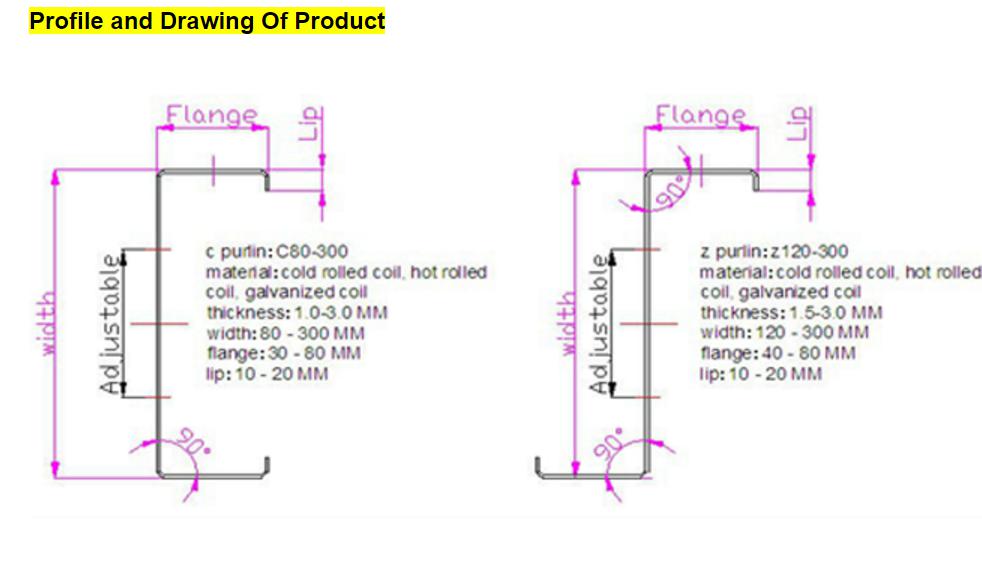

Here is the C & Z purline drawing profile for your reference:

What features fully automatic Cee, Zee Purline rolling forming Machine benefit you?

1.Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment.with black treatment or Hard-Chrome Coating for options.

2.With feeding material guide, body framemade from 400# H type steel by welding.

3.Produce different purlin size without changing rollers or spacers.

4.No need changing cutter for different size.

5.Easy operation, low maintenance cost

6.Infinite sizing(any size within machine range),help to save material

7.Optional Punch hole at any position of purlin web side and flange side

Here is the Cee, Zee Purline rolling forming Machine pictures for your reference:

Here are parameters of Cee, Zee Purline rolling forming Machine:

1. Guiding material into the machine

2. Barrier to Adjust material

3. Seven leveling rollers: three up and four down 4. Hydraulic cutting

Material : Cr12 steel with quenched treated 60-62℃

Cut the sheet after roll forming to required length

5. Feeding roller (Side roller) : a pair

6. Shaft material & shaft outer diameter

45# steel adjustable treatment,,80mm , Precision Machined

Rollers material: GCr15, 9CrSi, quenched treated HRC58-62℃

Rib roller material: GCr15, 40Cr, quenched

7. Stations: Main forming: 20 steps

Rib making: one step

Rectifying: one step

8. Motor; 18.5kw

9. Forming speed: 10-18 m/min

Time cost from one profile to another profile: 15m/min

10. The size: 15400 x 1800 x 1800mm

Please learn more about the C Z purline rolling machine by video here:

Next: Fully automatic door frame making machine