C section roll forming machine

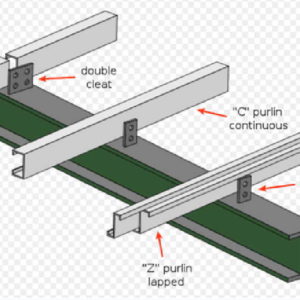

C sections are made from galvanized steel and can be used in conjunction with Z purlins and side rails for the same building. C sections can be used as an alternative to side rails, sitting on cleats between columns or on the face with the same section size as a Z purlin, they can cover bays up to 9M in length. They also have enough strength that they do not always require side rail supports or diagonal wires ties. The flat sections makes a C Section perfect for above doors / windows or a door frame.

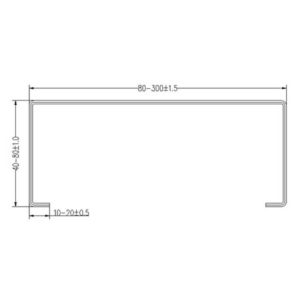

Here is the drawing profile of c section

A building with a brickwork base requires a closing section that can be easily fixed to without leaving a cavity. C Section is perfect for sitting on top of the bricks and blocks offering a solid base to build from. There are some detail parameters of the c section roll forming machine for your reference.

Forming steps: 16 rollers

Shaft diameter: 90 mm

Design type: Middle plate welded

Machine frame: 400# H steel welded

Roller material: Gcr12 steel

Shaft material: 40 CR

Working speed: 15 m/min

Transport: by chain

Power of main machine: 18.5 kw

Type of cutting: hydraulic

Cutter: Cr12

Working pressure: 20 Mpa