Shutter Door Machine

Shutter Door Machine

-

Shutter Door Roll Forming Machine

Description: DETAILS INFORMATION What is Shutter Door Roll Forming Machine? A roller shutter door forming machine is an automatic rolling machine to make shutter door slats. Roll up door r... -

Continuous PU Garage Door Panel Production Line

Continuous PU Garage Door Panel Production Line Continuous PU Garage Door Panel Production Line is designed to produce the Garage Door Panel in batch fully automatically. Garage door system, sur... -

Zhongtuo rolling shutter door track door rail roll forming machine

Zhongtuo rolling shutter door track door rail roll forming machine Zhongtuo rolling shutter door track door rail roll forming machine is designed to produce the shutter door rails in batch fully... -

Rolling shutter door machine

Here we share one article about the rolling shutter slat machine-single rolling shutter machine. As to the single roller shutter slat means the slats roll formed from galvanized steel or colour ste... -

Italy design rolling shutter guardrail rolling forming machine

Italy design rolling shutter guardrail rolling forming machine could be used to make shutter guardrail in batch fully automatic. The guardrail design is from Italy, when used together with the seal... -

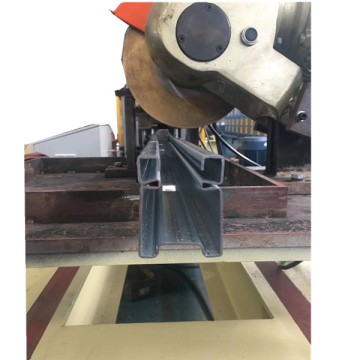

The gear box transmission and hydraulic cutting system door frame roll forming machine

The door frame roll forming machine is used to produce the door frame in large quality, which used in to steel door structure. There are 3 types of this door frame machine in designing: 1Door fram... -

Low cost rolling shutter door forming machine

Low cost rolling shutter door forming machine could be used to make the rolling shutter door panel in batch and fully automatic. The main feature of this type rolling shutter is cost lowest but qua... -

Half automatic door frame & window frame rolling forming machine

Zhongtuo Window and Door frame Rollforming machines are specially designed to produce steel window or door frames that are strong and durable. This article I will share some information about the h... -

Garage door roll forming machine

Roll forming for garage door panels and garage door track, all machines we can do for you.The whole process for manufacturing insulated garage doors and track is from the uncoilers to leveling beac... -

Garage door tracks guide hardware rolling machine

Garage door tracks rolling forming machine is designed to make the garage door tracks for house in batch and guide the rollers, which facilitate smooth travel of the garage door. Garage door tracks... -

Galvanized layer ringlock scaffolding roll forming machine

Scaffolding, also called scaffold or staging, is a temporary structure used to support a work crew and materials to aid in the construction, maintenance and repair of buildings, bridges and all ot... -

Fully automatic M door frame rolling forming machine

Fully automatic M door frame rolling forming machine can roll form different kinds metal door or window frames, reinforced, fire stop doors, etc. The punching also can be designed according to your... -

Fully automatic door frame making machine

Fully automatic door frame making machine could be used to make the door frame in batch and fully automatic. From tradtional method, normally door frame making machine only can be used to make shap... -

PU foamed roller shutter door roll forming machine

PU foamed roller shutter door roll forming machine could be used to make various sizes and types rolling shutter door by roll forming principle. The working flow of roller shutter door roll forming... -

Shutter door slat roll forming machine

Shutter door slat roll forming machine according to our knowledage there are serval types: European style shutter door machine, Australia style shutter door machine, shutter door with big holes, sh... -

Shutter door slat roll forming machine

In the market, there are many types slider rail of rolling shutter door, like molding type of aluminum, or simple U channel or others. But here I share one type of rolling forming type, something l... -

Shutter door U channel rolling forming machine

Shutter door U channel rolling forming machine, it is also called U channel guardrail rolling forming machine. The function is U channel guardrail is that it is for fixing the shutter door to the r... -

Shutter door U Channel roll forming machine

Rolling shutter door is quite popular in Europen at the beginning, but now it is quite popular all over the world. In many European countries, such as Germany, Italy, France and Spain, roll shutter... -

Strut channel with punching fully automatic production line

Strut channel is also called G-STRUT", "Kindorf", "Unistrut", "Superstrut", "UltraSTRUT", "Strut", "Metstrut", "Flexstrut", "JIKAstrut", "Nu-Strut", "Cantruss]", "C-Channel", "Canstrut, "Hilti Stru... -

Door frame roll forming machine with Gear transmission and non stopping cutting system

Door frame machine is a kind of roll forming machine, using the rolling station after station, to form the required door frame. The steel door frame is now widely used in buildings, there are cut f... -

Door frame roll froming machine

Door frame roll froming machine could be used to make metal door in various types in batch fully automatically. Door frame roll froming machine can produce plastic window steel liner, door lining s... -

Different kinds of solar panel frame

Solar panel frame are used by photovoltaic manufacturers to produce raw materials, battery components, and other component products. Solar panel frame is divided into three kinds according to the i... -

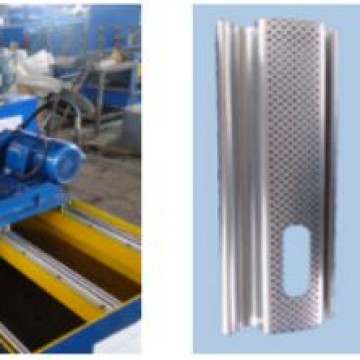

Auto-flying saw Perforated shutter door roll forming machine with holes

Shutter doors with walls as play a role in the level of separating. The shutter door is consists of the curtain plate, base bottom shutter door plate, rail, bearing U channel, reel, box, control bo... -

Cangzhou Zhongtuo Anti-fire Door Making Machine

The anti door is a kind of door with the characteristics of fireproofing and heat insulation. Anti-fire door is widely used in the buildings as the escaping staircase door. Anti fire door making ma... -

Water cooling down system of roll forming machine

What is water cooling down system of roll forming machine? Water as the cooling medium and a cooling water recycling system, it is mainly composed by the cooling equipment, water pump and pipeline...