Metal stud and track making machine

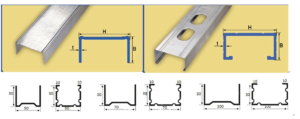

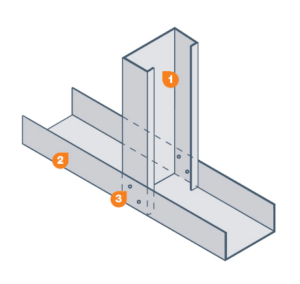

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. Most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, one of which is metal stud and track forming machine that has been designed for the continuous and automatic production of metal c stud and u tracks applied for both exterior and partition walls in both individual and industrial buildings.

Metal c stud and u tracks are great inventions in steel building projects, and that makes drywall stud and track roll forming machine, or even all the lightweight or light gauge steel frame roll forming machine highly popular in the international. A drywall stud and track roll forming machine usually consists of manual decoiler, a feeding guide unit, a punching tool, a roll forming unit, a cutting unit, a transimission unit, a hydraulic unit, a control unit, and runout tables. Under PLC control system, this drywall stud and track roll forming machine fully automatically produces 4-6 metal c studs or u tracks out of galvanized steel of 0.4-0.6 mm thickness from punching, roll forming and cutting.

Technical parameters of the metal stud and track making machine

1, Forming steps 10 rollers

2, Shaft diameter 40 mm

3 ,Middle Plate Structural

4,Roller material GCr12MoV quenching treatment 58-60°

5 ,Shaft material 40Cr steel

6 ,Work speed 0-25 meters/min

7, Gear transmission

8, Hydraulic

9,Cutting tolerance ±1mm

10,Cutter Gcr12 Gcr12

11,Working pressure 40MPA