Blog

-

Esquinero profile roll forming machine

The esquinero profile strip is a kind of profile that is used on the wall to make the corners more clean and beautiful. In addition to aesthetics, the esquinero profile strips reinforce the corners at the same time, avoiding dents and other damage in the corners. There are many types of corner ba...

-

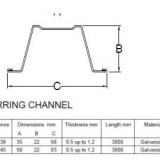

Drywall furring channel making machine

Drywall Furring Channel is a hat-shaped framing accessory designed to "furr" out any surface for the application of the final finish (ie. metal siding on steel studs, drywall on masonry, etc.). In addition furring channel used in conjunction with cold rolled channel is the ideal system for the co...

-

Steel door frame roll forming machine

Steel profile door frame roll forming machine can make various types metal door or window frames, reinforced, fire stop doors, etc. by roll forming method. The steel door frame roll forming machine is a complete product line. After roll forming by our production line, we could make very smooth an...

-

CU prulin making machine

As the main force part in the construction, our CU purlin making machine can make different sizes CU purlin for you. This CU Purlin making machine, can produce C shape and U shape purlins from 100-400mm of width and easily to change spacers. Maximum thickness can be formed at 1.5-3mm. Also we c...

-

Keel steel roll forming machine

Keel steel roll forming machine with a small dimension, easy to transport. The speed can be up to 60m/min. With the transmission, so the working will be more stable. We can also supply the customized machines. The finished products are widely used in decoration, interior decoration, etc. Take so...

-

Cold rolling machines

Cold rolling machines is used to reduce the temperature of the material being worked with while also increase how hard and strong the material gets during the rolling mill process. During this process, the overall finish and granule structure of the material is made more pure and workable. Our...

-

Two waves highway guardrail machine

Two waves highway guardrail machine can produce different size of 2 waves guard rail which used for highway or other livestock farms. The finished products are used as a variety of guardrail, highway guardrail, fence and other livestock farms. Take a drawing profile of two waves highway guardrai...

-

Cut to length line

The cut to length lines can cut an entry mother strip in cross section, forming sheets that are suitably stacked in compact and square packages. It can cut the matal sheet according to the customzied length. Let's show some information about the machine in the following. Take the picture of cut ...

-

Combined cut to length and slitting line

Combined cut to length and slitting line is a nulti-functional shearing machine, which can be used for slitting and recoilering, cut to length and stacking, and cut to length with stacking. It is so convinent fo r you to make cutting and slitting. Take a picture of combined cut to length and sli...

-

Box beam roll forming machine

Box beams are made from two identical channel sections nested together to form a box, Box beam is the most widely used beam, as the structure is the most strong compare with other type of beam.Box beam roll forming line is the essential for its production. The drawing profile of box beam Firs...

-

Z purlin making machine

Z purlin can attach roofing sheets or wall cladding. Our z purlin making machine can make z purlins and ensure ultimate durability. I will introduce more detail information about the machine in the following. A drawing profile of z purlin Picture and parameters of the Z purlin making machine ...

-

Ceiling panel forming machine

This type of sheet can be widely used in plant, house, storage and simple steel roof and wall. It has advantage of pretty appearance, durable using and so on. There are some main elements of the ceiling panel forming machine in the following. Decoiler: Usage: It is used to support the s...

-

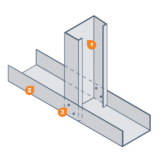

CU light steel profile forming machine

This CU light steel profile forming machine can produce C stud and u track for walls and truss framing. This kind of machine is mainly composed of uncoiler and its base, coil sheet guiding and adjusting device, roll forming system, punching system (optional), hydraulic post cutting system , PLC c...

-

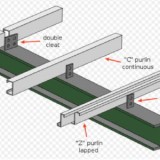

The usage of c purlin roll forming machine

The main purpose product of C purlin roll forming machine can be used as the main force structure of large and medium-sized industrial and civil buildings. The C purlin roll forming machine is a single-roll forming unit that can produce a variety of C-type purlins. The machine is mainly composed ...

-

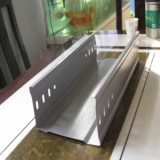

Cable tray roll forming line

A cable tray system, is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways." Cable trays are used to hold up and distribute cables. Cable tray roll forming machine is special designed for its pr...

-

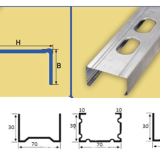

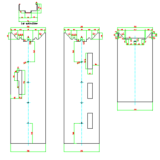

Metal door frame roll forming machine

Metal door frame roll forming machine is a production line to make metal door frame. We can customize the machine according to your requirements. In the following, i will show you some information about a metal door frame machine we made before. Take a drawing profile for your reference The w...

-

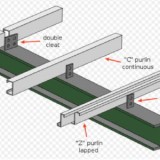

C section roll forming machine

C sections are made from galvanized steel and can be used in conjunction with Z purlins and side rails for the same building. C sections can be used as an alternative to side rails, sitting on cleats between columns or on the face with the same section size as a Z purlin, they can cover bays up t...

-

C purlin machine

With the adoption of PLC control mode and AC variable-frequency speed regulation technology, our C purlin machine is high efficient for continuous producing purlines. Its raw materials are coiled steel sheets and its main components are decoiler, guiding system, leveling system, pre-cutting syste...

-

Ceiling T-bar

Ceiling T bar are made of galvanized steel and color steel. It has three items: main T-bar, middle cross T-bar and wall angle. This production can be made of different size which is according to different size of ceiling board. Ceiling T grids has many advantages, include: beauty, good strength,...

-

Light steel keel

Light steel keel has more usage in modern construction. Ceiling channel and drywall channel, made of high- quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel...

-

Pallet racking production line

Pallet Racking is a cost effective storage system providing direct access to all pallets. It provides high capacity storage, is easily installed and adjusted, and has low equipment and capital costs. We have rich experience in making pallet racking production line, and can customize the machine a...

-

Metal stud and track making machine

In modern buildings, people tend to use steel because steel is lightweight, recyclable, costs less money and time, compared to traditional clays, stones or bricks. Most of building materials are made of steel, and most of these steel building materials are manufactured by roll forming machines, o...

-

Cable tray roll forming machine

The Cable Tray Roll Forming Machine produced by us, is used for producing cable trays that are used in different kind of factories and buildings. We offering you to cable tray machine that comprise of efficient Punching Press, Hydraulic Press, Electric Control penel and many other Equipment, whic...

-

Z purlin roll forming machine

Z purlin roll forming machine works in the same principle as a c purlin roll forming machine does for producing steel purlins for metal building systems, only the purlins’ shapes make difference. Z steel purlins can be used for a variety of applications, but 90% for steel structural building s...

-

C shaped section channels roll forming machine

C shaped section channels roll forming machine is an equipment that produces C shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, bending and cutting. Nowadays, people developed stone or concrete purlins which were strong enough t...

-

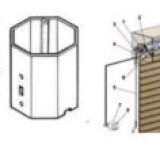

Octagon pipe roll forming machine

An octagon pipe roll forming machine is an equipment that manufactures the octagonal axes of roundel for rolling shutter doors that is assembled by steel slats or metal sheet panels. As its name shows, Octagonal tube is new type building material. Octagonal Tubes are widely used in petroch...

-

Steel rolling shutter slat roll forming machine

A steel rolling shutter slat roll forming machine has been designed to produce horizontal roller shutter door slats out of galvanized or prepainted steel strips. A rolling shutter door or roller shutter door is a type of door that consists of many horizontal slats hinge together and the door open...

-

Metal stud furring channel roll forming machine

The metal stud furring channel roll forming machine has been designed for the manufacturing of hat shaped furring channels. And the hat shaped furring channels used to build lightweight or light gauge steel buildings. Being one of the roll forming machines for the production of lightweight or ...

-

Crash barrier roll forming machine

The crash barrier roll forming machine has been designed for producing w shaped guardrails with 2 wave and 3 waves or thrie beams placed on both sides of highway or expressway. MTC designs and manufactures crash barrier roll forming machine for the making 2 waves or w beam and 3 waves or thrie...

-

Roll forming machine

Roll forming, also spelled rollforming or roll-forming, is a continuous bending operation in which a strip of metal (typically coiled steel or aluminum) is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend, until the desired cross-section...