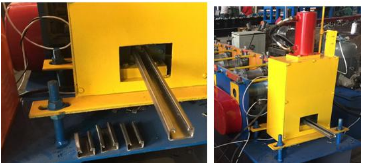

Strut channel roll forming machine

The strut channel roll forming machine is a high performance production line for manufacture various sizes of channel profile. It is made from light gauge to middle gauge steel. The strut channel is reusable metal profile widely used as pipe support, cable tray support, duct support and solar panel mounting frame etc.

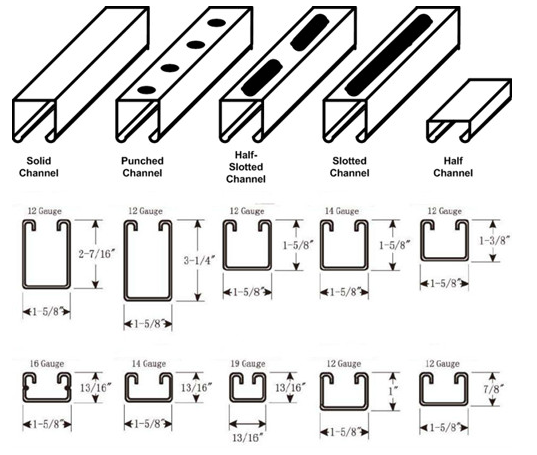

Check some drawings

Parameters of struct channel roll forming machine

1) Number of rolling stations: 16 rolling stations

2) Shaft diameter: 70mm

3) Shaft material: 45# steel after quenching.

4) Roller material: 45# steel after quenching.

5) Transmission method: by China

6) Chainwidth: 1.25mm

7) Machine working speed: 5-10m/min

8) Working speed: 5-10m/min

9) Motor Brand: Chinese famous brand MengNiu

10) Voltage: 380v, 50Hz,3 phases

11) Machine size: 9.5*1.5*1.2m

12) Machine frame: Middle plate

13) Machine frame thickness: 20mm

Features of struct channel roll forming machine

1. material with galvanised steel thickness from 1.5-2.5 mm

2. production speed of struct channel roll forming machine is 6-15 m/min

3. automatic "hands-free", PLC control system with touch screen

4. cut to any length by setting on touch screen in PLC system

5. stationary hydraulic cut off make accurate and clear cut

6.in-line punching press is equipped for hole slooting

7. option with flying shear to maximum product output

8. option with multi-profile roll tooling designing for product size changeover

9. option with auto-stacker to minimize operator cost