Product Details

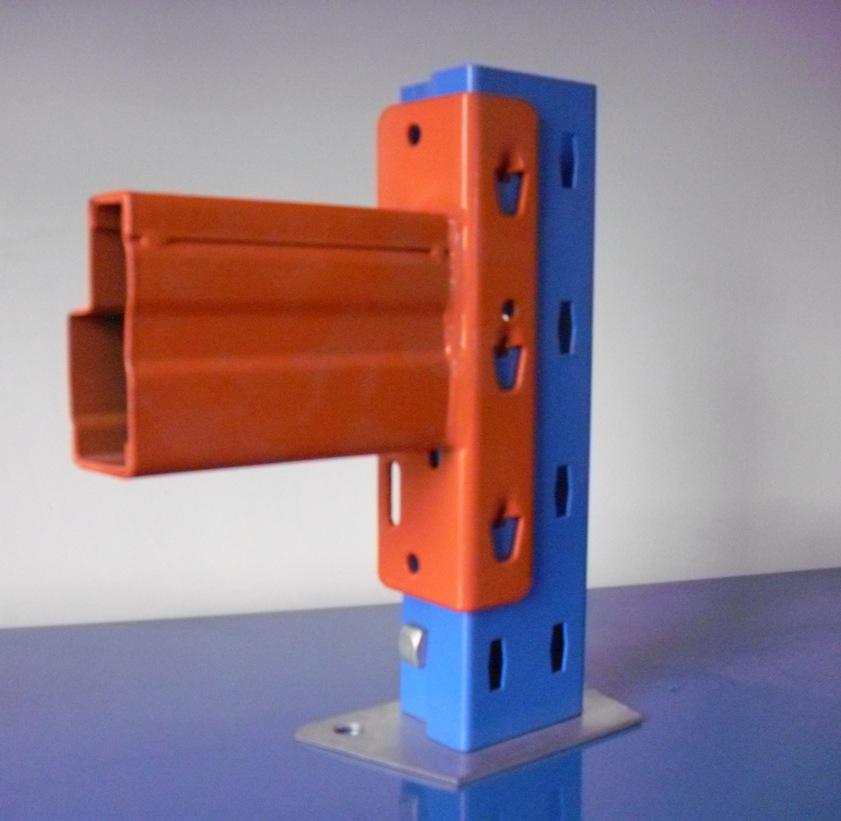

Shelf beam making machine/interlocked square pipe making machine could be used to make the square pipe by two C shape purlines. The machine takes advantage of the roll forming machine principle and interlocked method to make the building used pipes. For those square pipes made by those machine are size adjustable and there is seam.

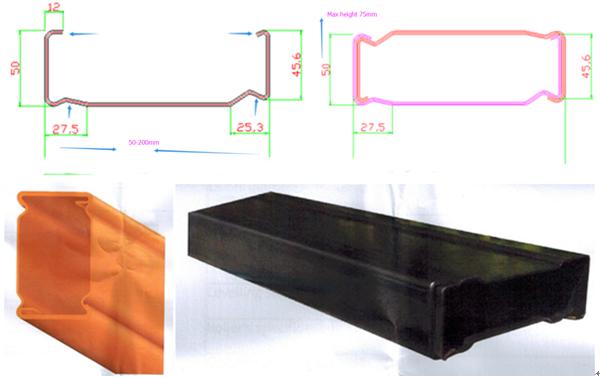

Meanwhile those pipes are also could be used as shelf beam for supermarket or warehouse and others. The box making machine is composed by two parts: one is the specail C shape channel making machine. The second part is interlocked making machine. Here are some drawing profiles and finsihed products pictures for your reference:

Here are the details parameters of the Shelf beam making machine for your reference:

| First part: C shape roll forming machine |

| This machine is composed by the following elements: decoiler, leveling beach, main roll forming machine, shearing system, hydraulic system, and PLC control system and runout table. |

| Manual decoiler: Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system 1:Coil inner diameter: 450-550mm 2:Coil max width: 600mm 3:Max carrying capacity: 5000kg 4: Expansion method: manual |

| Leveling beach: Put the coil feed into machine, and the making sure the coil neat, straight and clean |

| Roll forming machine 1: Coil width: according to the profiles 2: working speed:4-12m/min 3: roll station: 16 stations 4: material of roller: GCr12MoVsteel, 5: material of main shaft: 45﹟forge steel 6: Main power: 15KW. 7: forming thickness:1-3mm 8: Transmission: chain 9: size of machine: about 10.5×1.5×1.2 m( L x W x H) 10: weight: about 16000Kgs 11: color of machine: blue and yellow |

| Shearing system 1:Hydraulic working pressure: 16Mpa 2:Cutting after forming: Cut the sheet after roll forming to required length 3:Material of blade:Cr12 with heat treatment 58-60° 4:Length measuring: Automatic encoder length measuring, brand: Omron 5:Tolerance of length: 3000mm+/- 1.0mm 6:Cutting table length: 2m 6. Hydraulic power: 5.5kw |

| Hydraulic station 1:Hydraulic power: 5.5kw 2:Working pressure:20Mp adjustable 3:Solenoid valve: 1 groups 4:Hydraulic oil: 46# hydraulic oil 5:Quantity :2 |

| PLC station 1: The PLC powered by the software that controls the automation of the processes of forming cutting will be of the latest technology available and allow the operator through a touch screen enter quickly and reliably all data to Meet a predetermined production. 2: Automatic length measurement 3: Automatic quantity measurement 4: Automatic punching distances 5: Computer used to control length &Quantity. Machine will automatically cut to length and stop when required quantity is achieved. 6: Length inaccuracy can be amended easily. 7: Control panel: Button-type switch and touch screen 8: Unit of length: millimeter (switched on the control panel) 9: Language: English and Chinese 10: Brand: Taiwan Delta |

| Run out table It adopts welded steel and supported roller to transmit the products. |

| Machine pictures for your refernece |

Prev:

Supermarkt shelf panel roll forming machine

Next: Shelf beam making machine/interlocked square pipe making machine

Next: Shelf beam making machine/interlocked square pipe making machine