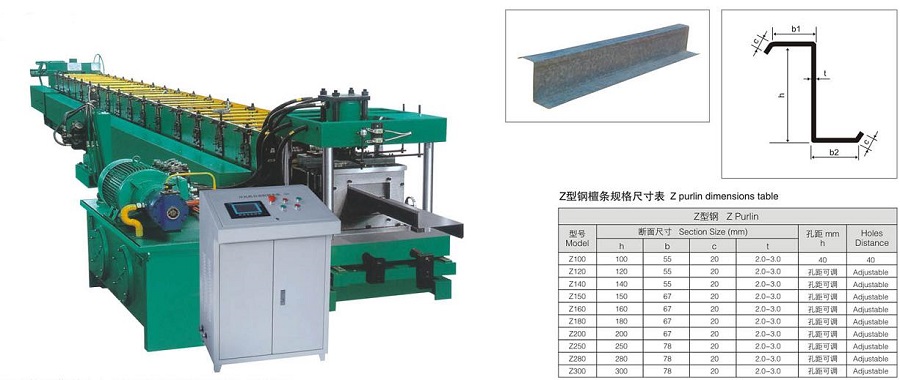

Z purline roll forming machine could be used to make various Z purline in batch. According to our experience, we have two types Z purline machines one is adjusting sizes by spacer and the other type is changing sizes fully automatic. For the fully autoamtic Z purline machine, learn more that page. Here I will mainly introduce the maunal type Z puline machine.

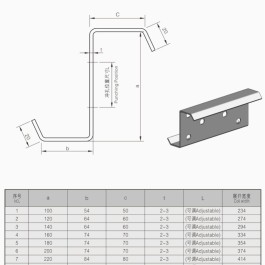

Z purline roll forming machine manual adjusting spacer version also could be used to make sizes of Z from 80 to 300, mater thickness from 2 to 3.5mm. And the punching holes either could be at the botton and at lip part. The machine is composed by the following elements: decoiler, leveling beach, roll forming machine, punching station, PLC control system, hydraulic station and runout table. For the Z purline size, please have a check:

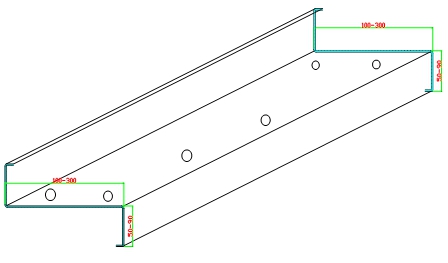

Detail drawing profile:

Working flow:

Passive Uncoiler—Feeding—Leveling-- roll forming --hydraulic cut to length—output table

Here are some parameters of Z purline machine:

1) Roll forming system (one machine for four sizes)

Main motor power: 18.5kw

Drive: Chain

Main shaft dia: ¢85mm, material: 45﹟refined forge steel

Roller material: GCr15 bearing steel, quenching HRC58-62,surface coated chrome with thickness 0.05mm

Roll station: 16stations with 7 leveling rollers

Raw material: Black steel or galvanized steel

Thickness of raw material: 2-3mm

Working speed: about 7-15m/min(include cutting time)

Coder: OMROM

PLC: YASKAWA, made in Japan. 380V 50HZ(Depend on customer)

Computer operating panel: touching screen

2).Shearing system

Hydraulic cutting

Four sets of the cutting mould to replace for different size

Hydraulic power: 5.5KW

Hydraulic pressure: 20Mpa

Blade material: Cr12mov, quenched 58°-62°

If you need the fully automatic version of asjusting sizes, please refer to fully automatic Z purline machine. If you want to know more information about this machine, please contact us at any time.

Next: Zhongtuo factory is sorry for delaying shipping the machines to customers