Fully automatic flat T bar machine is developed to make ceiling T bar fully automatic without people to intervene. For making the whole set ceiling T gird, you need to make main T, cross T and wall angle . The machine is composed by the following elements: decoiler, feeding device, roll forming machine, hydraulic cutting part, hydraulic punching part, hydraulic station and electric control system, etc.

Here are some normal T sizes for your reference:

38H Model:

I) Main tee: 38mm x 24mm x 3.0m, or 3.05m, 3.60m, 3.66m

Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m

Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m

Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m

V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm

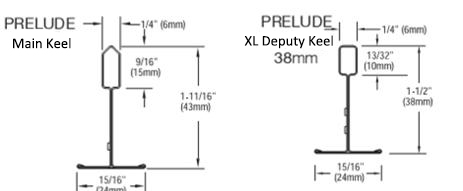

Here is the drawing profile for your reference:

Machine working process:

The profile forming process: Passive decoiling--- material feeding--- roll forming--- hydraulic cutting off---- hydraulic punching--- material unloading, all the process finished automatically

Here is machine picture for your reference:

1.Decoiler

Bearing 1.5 Ton

Inner diameter φ450-530mm

out diameter φ1200mm

Quantity: 2 sets

2.Feeding device:

synchronism adjusting rollers.

3. Roll Forming Machine

Roll Forming rollers: material GCr15, hardness after heat treatment HRC48-50, hole diameter (roller shaft diameter) φ42mm, the min. outside diameter of rollers isφ100.

4. Transmission Device:

a. Main motor, Frequency control.

b. The driving rollers are driven by three sides belt, the passive rollers are driven by gears, with center distance a=75, reduction ratio i=30 worm gear case, gear mould m=5. Main side plate thickness: 30mm, deputy side plate thickness: 25mm. Finished by six sides grinding and boring holes treatments.

c. The material of main shaft is 40Cr, finished after heat treatment and refine grinded.

5. Hydraulic Cut Off device

a. Hydraulic system: the system has unloading protect function.

b. Mould rack: the mould plate closed height is 260mm; the adjustment range of the closed height is 20mm, the max. Stroke of oil cylinder is 100mm.

c. There is straight guide track under the mould rack, the relocation of the mould rack replying the push of buffer pneumatic cylinder.

d. The cut off mould: design as the botch of the production, equip with another cut off mould.

6. Punching Machine

This line equipped with fully automatic hydraulic punching machine.

7. Electric system

A. Use frequency converter, centre auto control, uses the fixed rule to adjust the length and automatic cut off. When the punched mould is cutting off, the roll forming machine lower speed automatically, when the cut off is finished, it goes to high speed again.

B.PLC is composed by human-machine interface, button, switch, emergency stop, etc. Multi- languages supported. You can specify length, pieces and others in the PLC

C. Alarming function: stop when lacking material, count the numbers, stop when the production number is finished, alarming when transmission failure, emergency stop, mould stuck, position limited, etc.

Note: Installation of electric components obeys local rules. All the electric components have clear marks. In the electric cabinet, we use anti-flaming plastic slots to arrange the wires. The number of the wires is clear, the layout of the components is reasonable, the control panel is tidy, the marks are clear.

Working Environments

1) Power supply: voltage 380V±10%/ three phase four wire, frequency 50HZ.

2) Total power: 12kw

3) Air rate: 10.0L/min (air pressure 0.4-0.6Mpa)

4) Environment temperature: 0°C-40°C, relative humidity: 60-95%RH.

Other sizes of the T bar for your reference:

32H Model

I) Main tee: 32mm x 14.5mm x 3.0m, or 3.05m, 3.60m, 3.66m

Ii) Cross tee: 32mm x 14.5mm x 1.2m, or 1.22m

Iii) Cross tee: 32mm x 14.5mm x 0.6m, or 0.61m

Iv) Wall angle: 20mm x 14mm x 3.05m, or 3.60m

V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm

38H

I) Main tee: 38mm x 14.5mm x 3.0m, or 3.05m, 3.60m, 3.66m

Ii) Cross tee: 38mm x 14.5mm x 1.2m, or 1.22m

Iii) Cross tee: 38mm x

14.5mm x 0.6m, or 0.61m

Iv) Wall angle: 20mm x 14mm x 3.05m, or 3.60m

V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm Besides ceiling

Here is the machine working for your reference:

When need for final quotation, please contact us at any time.

We also have Cross tee supended ceiling grid t trim making machine.

Next: Fully automatic high speed drywall making machine