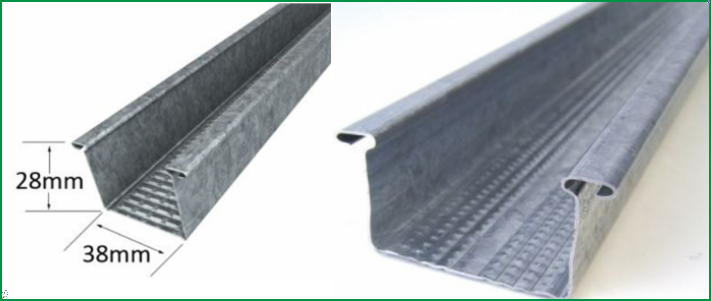

Suspended ceiling furring Channel rolling forming machine is designed to make the ceiling furring Channel in batch fully automatically. Concealed Suspended Ceiling System is designed to produce a high-quality structure for a flush or featured finish to your plasterboard ceiling. It has the following features of 28mm (h) x 38mm (face):

Suspended ceiling furring Channel 28x38 type has the following features:

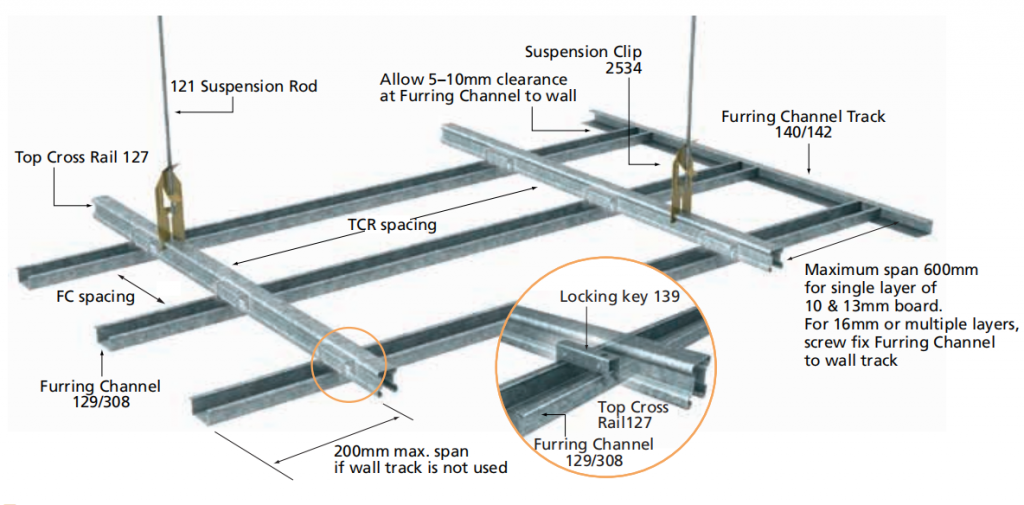

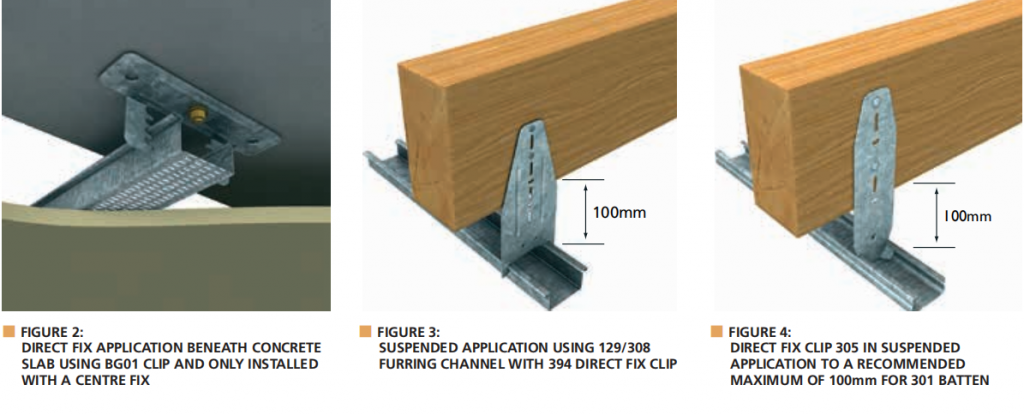

- Ceiling furring Channelin both direct fix and suspension applications.

- With special lock method with suspension clips simplify the assembly of components

- Mid-span joiners for both primary rail and furring channel sections eliminates waste, and speeds up erection time

- A range of furring channels, battens and primary rails allows for variable spanning and spacing options

- Ability to hold multiple layers of board due to its high-quality structure

Based on those features, this profile became popular fast in the market. So the demand of the metal rolling forming machine became huge. Zhongtuo metal cold rolling forming machine design like the following:

Why ZHONGTUO Suspended ceiling furring Channel 28x38 type rolling forming machine can benefit you:

Suspended ceiling furring Channel 28x38 type usage and installation:

Note:Direct fixing clips need to be fixed along the sections in accordance with the relevant maximum span tables and each Furring Channel is required to be spaced as per the building board manufacturers' recommendations.

Here is the similar machine working videos for your reference:

Next: How we design machine and why Zhongtuo machine production time is around 60 days?