Product Details

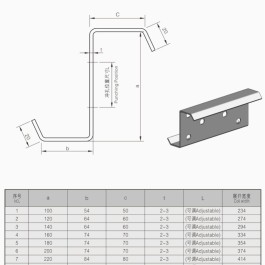

High speed omega channel roll forming machine double sizes could be used to make omeage channel in large quantity. The working speed could reach 50m/min. This machine we made for Australia customer is for making furring channel like the following drawings:

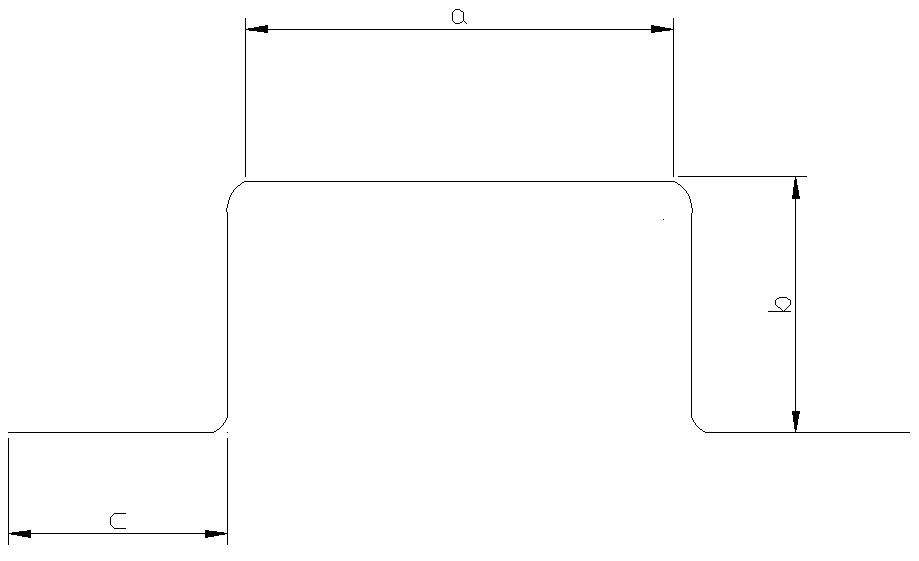

Profile 1: a = 50mm, b= 24mm, c = 20mm

Profile 2: a = 50mm, b= 15mm, c = 15mm

The material could be SG350, SG550, stainless steel or normal carbon steel.

The machine we designed like the following pictures:

FFor this machine, if you need to know more information, please contact us at any time.

Prev:

Double roll forming machine delivery

Next: 50, 75, 100 drywall light keel roll forming machine

Next: 50, 75, 100 drywall light keel roll forming machine