Stainless steel handrails second roll forming machine could be used to make stainless steel handrail in batch. The old shaper process involved heavy, machined aluminum plate-templates along with fixed toggle clamps and guarded hand-grips. The actual cutting was usually done in two passes against an adjustable lower or upper ring and enclosed dust hood. Now we make the handrails by the roll forming machines. In stead of the wood material, now we use the metal, stainless steel and others.

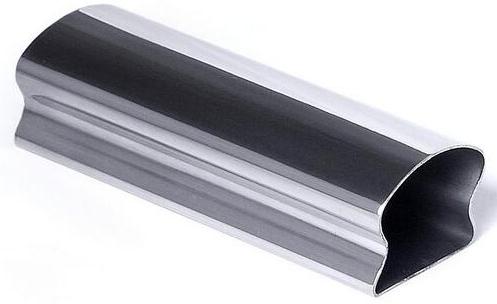

Here are some sample pictures for your reference:

We make this type pipe from the round pipe by the second roll forming machine. Actaully one set of stainless steel handrails second roll forming machine can support two types' different drawing profiles.

Here are some machine parameters for your reference:

|

Machine parameters for your reference |

|

|

Machine size |

3000*1350*1000(mm) |

|

Main power |

7.5KW |

|

reducer |

350 heavy duty type |

|

Input pipe daimeter |

48mm and 59mm |

|

Roller station |

9 roll forming machine 3 leveling and sizing rollers |

|

Supported materail thickeess |

≤2mm |

|

Working speed |

10m/min |

|

Roller mateiral |

GCr15 processing after heat treatment |

|

Shaft material |

40Cr quencing |

|

Shaft diameter |

60mm, processed from 70diameter round bar |

|

Bearing |

6313 type |

Turn the iron handrail on a metal lathe for a smooth rounded surface before bending. Afterwards, you will not be able to vary the surface features easily. Here is one picture about the real use of the stainless steel handrails.

If you are interested in how this stair rail is made, please refer to the following video:

Next: Square downpipe rolling forming machine