Cable tray roll forming line

A cable tray system, is "a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways." Cable trays are used to hold up and distribute cables. Cable tray roll forming machine is special designed for its production. Cable tray roll forming line include whole line of can automatic produce wide range of cable tray to meet different customer requirement. Also it has more options Pre-Cutting and Post cutting, hydraulic punching and independent press machine, manually adjust size and automatically changes sizes.

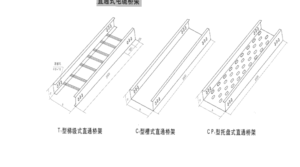

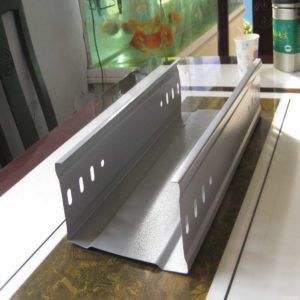

Some drawing profiles and finished product

Some detail parts of the cable tray roll forming line

Components:

1.Decoiler

2.Leveling machine

3.Servo feeding device to make sure holes precision

4.Punching system with punching tools (hydraulic punching and independent press machine)

5.Cutting device( Pre-Cutting and Post cutting )

6.Guiding conveyor device

7.Roll forming machine

8.Run-out table

Parameters:

1.Raw Material Type: cold rolled steel or galvanized sheet, stainless steel

2.Raw Material Thickness: 1-2.5 mm

3.Roll Forming Speed: 10-15 m/min

A working video of the cable tray roll forming line for your reference

About other information of the machine, please feel free to contact with us.