Half automatic interchangable CZ purlin machine

The half automatic interchangable CZ purlin machine can produce various specifications of CZ purlins by half automatic simple stepless adjustment using the same set of equipment. It is not necessary to change the forming rolls when changing specifications. The production process adopts automatic control mode, which can automatically punch, cut and form according to the input length, longitudinal hole distance and quantity.

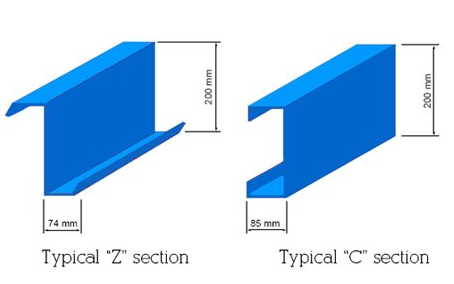

Check the drawing profile

Technical parameters of half automatic interchangable CZ purlin machine

1.C/Z purlin processing specifications:

By customer shape chart (width 300, height 100)

2. Processing workpiece thickness: 1.5~3mm

3. Punching hole distance lateral adjustment range: 45~500mm

4. Board length: >3m

5. Large forming speed of C-type purlin: 20m/min

6. Installation form: using the arch type

7. Roller form: using two-side rollerway split type

8. Roll material: GCr15 steel quenching treatment

9. Spindle material: 45 steel quenching and tempering treatment

10. The main motor power is about 15KW

11. Width adjustment total motor power: 3KW

12. Drive form: chain drive

13. Number of rollers: 17

14. Punching, cutting: hydraulic drive, flat punching, flat cutting

15. Cutter material: Cr12 quenching treatment

16. Electronic control system: the whole machine adopts industrial computer PLC frequency conversion control

The whole machine has beautiful appearance and high production efficiency (production speed reaches 20m/min).