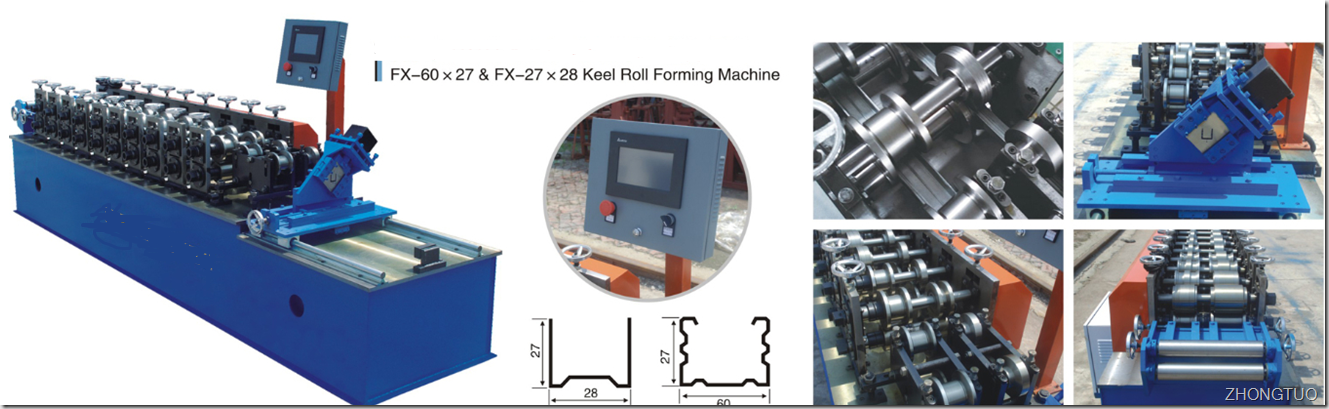

Quotation-60*27-28*27 Light Keel Roll Forming Machine

60*27-28*27 Light Keel Roll Forming Machine is something like combined type light keel machine. By this one machine, you can make 60x27mm stud, 27x28mm track and others. All those three elements is quite important for drywall building. When you need to start drywall work project, I feel this one machine is enough for you.

The machine can process material: GI and others Material thickness: 0.4---0.8mm

Material hardness: 550 MPA---350 MPA Formed width: 28/60mm

Forming speed: 20m/min

Here are some drawing profile for your reference:

The machine is composed by the following elements: decoiler, leveling beach, roll forming machine, shearing and punching system and the runout table. The machine is fully automatic and controlled by PLC. So you can control machine working speed, shearing length and accuracy.

Here are the machine elements details for your reference:

Decoiler:

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 1.5T Uncoiling width: 300mm Inner diameter: 450-550mm

Entry Beach

Usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate board.

Main Roll Forming System

Feature : Ensure stability , precision and lifetime.

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission( the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating , heat treatment and galvanization treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 3000х1000х1400

Weight of main part: 3 tons

Voltage : 380V/50HZ3Phase (as customer’s request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers : 10 rollers

Main power: 3kw

Cycloidal planetary gear speed reducer)

Double working lines on the machine to finish the two profiles. Change the feeding unit to make another profile, the cutting head can move left and right by hand!

Shearing Mechanism

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Gcr12MoV quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Components: It contains one set of cutting tools, one hydraulic tank and one cutter machine.

Here is the each part picture of machine for your reference:

For this machine, if you want to know more information, please contact me at any time or sending us an email to cnzt002@zhongtuocn.com