Steel door frame roll forming machine

Steel profile door frame roll forming machine can make various types metal door or window frames, reinforced, fire stop doors, etc. by roll forming method. The steel door frame roll forming machine is a complete product line. After roll forming by our production line, we could make very smooth and beautiful steel door frame without any scratch on surface.

A drawing profile of the stee door frame

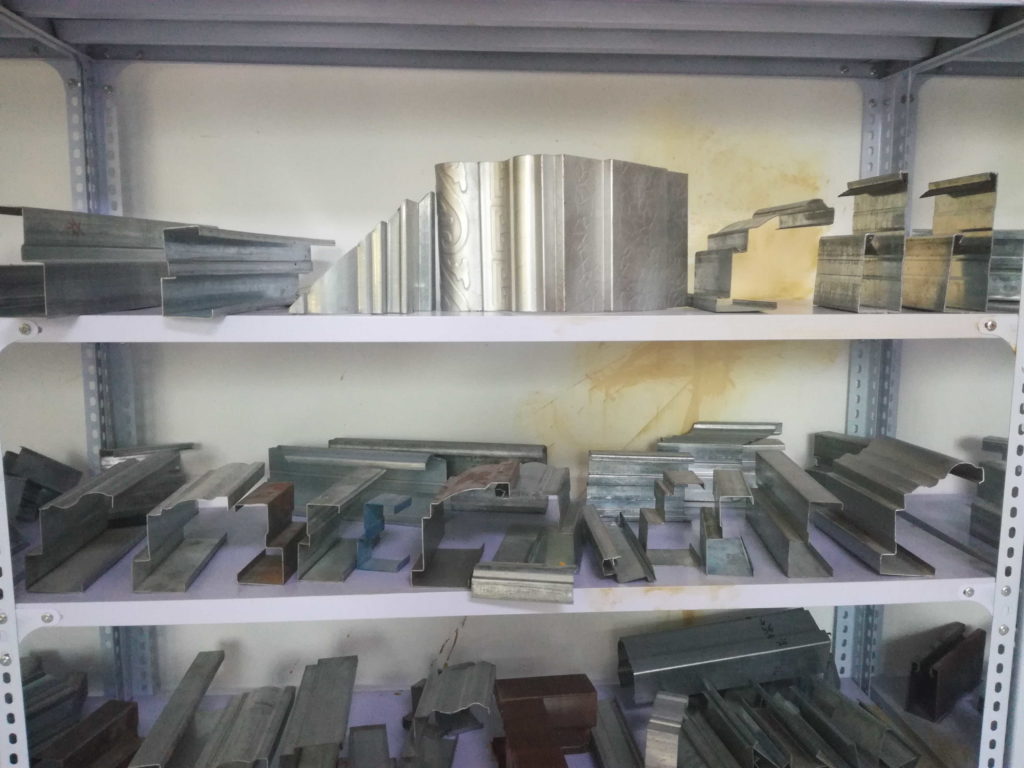

Some finished product of steel door frame

Main parameters of steel door frame roll forming machine

Manual decoiler

1).Material coil inner diameter: 500mm-600mm

2).Max coil width: 600mm

3).Carrying capacity: 1500kg

Forming system

1).Shaft material:45# steel,outer diameter:50mm

2). Roller material:CR12Mov

3).Number of forming steps:14steps

4).Main electrical machinery power: 7.5 KW

5).Forming speed: 25m/min

6).Transport:by gear

7).Voltage: 380v 50hz 3phase

Cutting system

1).Hydraulic cutter

2).Blade and mold material: Cr12 steel with quenched treated 60-62℃

3).Cutting system: advanced hydraulic drive, automatic cutting after forming,no distorting or wasting,high level safety factor,will not stop the machine to ensure the speed of cutting.