Steel rolling shutter slat roll forming machine

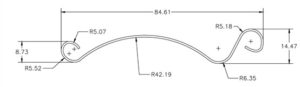

A steel rolling shutter slat roll forming machine has been designed to produce horizontal roller shutter door slats out of galvanized or prepainted steel strips. A rolling shutter door or roller shutter door is a type of door that consists of many horizontal slats hinge together and the door opens and closes by raising up or lowering down along a rolling shutter door track or guide rails.

Compared to a traditional door, a roller shutter door has different close or open method. A traditional door is open or method by rotating from 0-90 degress, while a roller shutter door opens and closes by raising up and lowering down, and the ending of a roller shutter is a roundel along which the shutter door will be rolled when raised up.

Another difference is a roller shutter always changes its shapes when closing and openning (a roller shutter door is square or rectangular shape when lowered down to close and it becomes a barrel or drum shape when raised up to open) due to its composition structure; while a traditional door changes only position not the shape itself.

The following are some parameters of steel rolling shutter slat roll forming machine

Material thickness: 0.8-1.2 mm

Roll station: 14 stations

Motor power: 4+4 kw

Productivity: 0-20 m/min

De-coiler capacity: 1.5Tons

PLC brand: Delta or customized