60X27 stud and 27X28 track roll forming machine

In modern society, c stud and u track are mainly used for false ceiling making and drywall making. CU keel systems are easy to handle, economical, non-combustible, high quality alternate to more traditional framing materials such as wood. Non-load bearing steel framing includes: steel studs and track. I will introduce the 60X27 stud and 27X28 track roll forming machine to you.

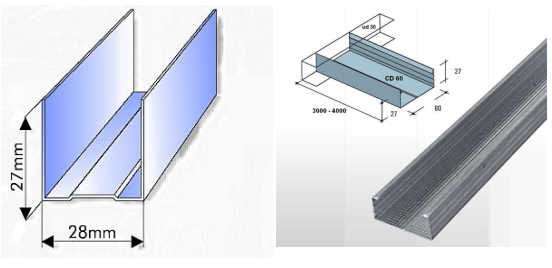

Check the drawing of the 60*27 stud and 27*28 track

Main parameters of 60X27 stud and 27X28 track roll forming machine

Manual Decoiler

1).Material coil inner diameter: 450mm-550mm

2).Max coil Width:400mm

3).Carrying capacity: 1.5T

Forming system

1).Roller station:10stations

2).Shaft material:45# steel

Outer diameter:40mm

3) Roller material: Bearing Steel

4).Transport: Gear Driving

5).Forming Speed: 15-20m/min

6).Motor:3kw

7).Size of Machine: 5mx1.2mx1.5m

8).Voltage:380v,50Hz,3 phase

Cutting System

1).Material: blade and mold material: Cr12 steel with quenched treated 60-62℃

2).Cutting system: Advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor.

Control system

1) Screen: touch screen

2) PLC:Taiwan Delta

3) Automatic length measurement

4) Automatic quantity measurement

5) Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved

6) Length inaccuracy can be amended easily