Omega light keel roll forming machine

Omega light keel roll forming machine

Keel machine is based on strip as raw material, through continuous cold-rolled forming, production the complex cross-section profiles (products: steel keel, paint keel, keel, Etc.) and different specifications of the cold-formed, paint unit equipment, controled by PLC .

Profile pictures for reference:

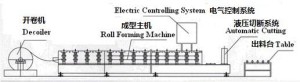

Component:

Un-coiler System:

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

Entry Beach:

Usage: Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Main Roll Forming System:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission( the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Hydraulic Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Electric Control System

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Counter

One counter gauges length, pulses, and decides length.

Omron encoder for length measurement.

The light keel roll forming machine we shipped to Fiji: