Metal z purlins roll forming machine

Metal z purlins for supporting either roof sheets or vertical wall cladding. Our metal z purlins roll forming machine can produce the accurate manufacture of purlins to virtually any length. This traditional well proven system of sheet support offers a high degree of strength, flexibility and weight saving over timber or hot rolled steel sections with ease of handling on-site and during installation.

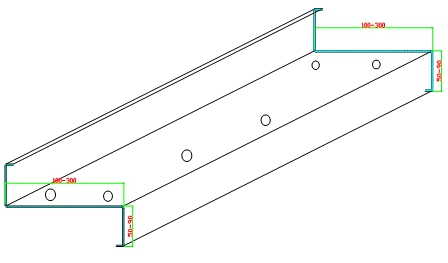

Check the drawing profiles of metal z purlins

Benefits of z purlins:

Manufactured to exact length

Maximum strength and long life

Lighter, stronger and cheaper than equivalent timber purlins

Parameters of metal z purlins roll forming machine

Forming steps 19 rollers

Shaft diameter 90 mm

Design type Middle plate welded

Machine frame 400# H steel welded

roller material GCr12 steel

shaft material 40CR

Work speed 15 m/min

Transport By chain

Power of main machine 18.5 kw

Type of cutting Hydraulic

Cutting tolerance ±1mm

Cutter quantity 1 set

Working pressure 20MPA

Applications of metal z purlins

It has the advantages of adjustable size and high compressive strength. It is widely used in automobiles, railway vehicles, building doors and windows, transportation, shelves, electrical cabinets, highway guardrails, building steel structures, containers, steel formwork and scaffolding, solar powered shipbuilding, bridges, Transmission towers, steel sheet piles, cable trays, agricultural machinery, furniture, storage, guide rails, keel steel, vegetable greenhouses, pipeline supports, municipal construction and other fields.