perforated shutter door steel cold roll form machinery

Perforated shutter door steel cold roll form machinery

Main Roll Forming System of perforated shutter door steel cold roll form machinery

usage: In order to keep the product shape and precision, adopts cast sheet structure, motor reducer drive,gear transmission,roller.

Length of the main part: about 5000*800*2000mm

Frame plate thickness :40mm

Weight of main part :3.2 T

Main power: 4kw

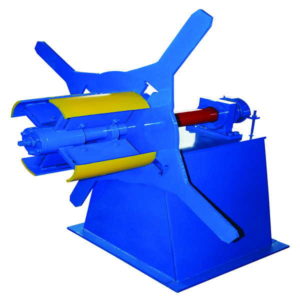

Shutter door roll form machinery Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way.Passive uncoil pulled by roll forming system.

Loading capacity:5T

Uncoiler width:300mm

Inner diameter:450-550mm

Shutter door roll form machinery Entry Beach

Usage: Put the raw material (steel panel)through the beach to manufacture and process, it can gurantee that the products are neat,parallel and everything is uniformity.Please refer to the equipment regulation to know the function of locate baffles.

And about the other parts of perforated shutter door roll forming machine, if you want to know, please feel free to send your requirements to us.

Main roll forming machine system:

1.Number of forming steps:12stations

2.Shaft material:45# steel with quenched treatment, precision machined,

3.The diameter: ¢50mm

4.Roller material:Cr15Movwith quenched treatment

5.Transport: by gear

6.Forming speed: 18-20m/min

7.Motor: 4kw

8.Voltage:380v, 50Hz,3 phase

9.Structure:independent stand

10.Size of machine: 4.5m*0.8m *1.2m

11.weight:1.8T