Blog

-

angle keel roll forming machine

Angle keel roll forming machine Angle keel roll forming machine equipment consists of: discharge machine, the guide frame, forming the host, correction means, length cutting portion, receiving station, consisting of electrical control and so on. Bed as steel weldments. And for tempering, elimina...

-

Light steel keel machine equipment

Strut channels keel machine equipment consists of the following equipment components: hydraulic uncoiler, five roll leveler shear welder servo feeder length measurement, utility hydraulic punching machine roll forming machine flying shear, out-feed conveyor cooling rack system, electrical system ...

-

purline roll forming machine

Z purline steel is not only a durable and economical advantages, while z steel throughout the production process of clean, environmentally friendly, z steel addition to the application with a number of large steel structure into the room, still rolling stock, transport, shelves, appliances cabine...

-

The introduction and application of color steel tile press machine in Chinese market

Color steel tile press as an indispensable professional production equipment in engineering construction environment.There is a set of lubrication system in the Color steel tile press.During the operation of the machine, it plays a role in lubricating all the bearings, the motion gu...

-

Industrial upgrading of the supply and demand market of color steel plate pressing machine

With the beginning of China's reform and opening up, the domestic economic growth rate has been growing rapidly for several years.China's industry is also developing rapidly along the fast lane. The high degree of perfection of the industrial chain of various major and subordinate machi...

-

Three factors of affecting the cost of steel structure plant

The steel structure workshop is destined to have a strong construction market share due to its beautiful appearance, short construction period, high degree of industrialization and resource reuse. The cost of steel structure workshop is also a concern of many people. It can be used to control the...

-

Characteristics and application of steel structures

Steel structures are mainly used in the following aspects: 1Industrial plant: It is adopted by industrial plant. It has small amount of steel, small base load, large span, high space use efficiency, comprehensive cost, flexible layout and convenient suspension. It is the most ideal structure for...

-

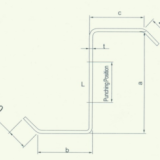

Features of steel purlin

The steel purlin is processed by cold-rolling. The wall is thin and light in weight, with excellent cross-section performance and high strength. The material is Q195-345. The steel stringer is a secondary load-bearing member of the roof structure system that transfers the roof load to the steel f...

-

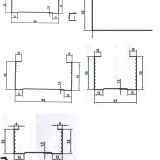

Stud/pop chanel rack roll framing machine

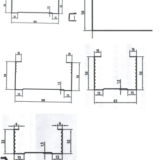

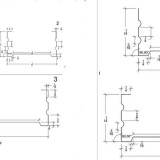

Steel stud made by this stud/pop chanel rack roll framing machine are suitable to use as building decorations, especially suitable to use in bedroom, kitchen, washroom, corridor and so on. There are some details in the followings for your reference. Drawing profile Parameters of stud/pop...

-

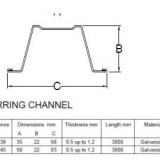

Z shape steel purlin roll forming machine

The Z shape steel purlin is processed from hot rolled steel. Though it is thin and light, it owns a high strength and excellent performance. It is usually used in large steel structure workshop, and it is also available in roof trusses, light industrial machineries, and other structural component...

-

Steel stud and track wall framing machine

The steel stud and track wall framing is an economical friction-fit system to assemble frames for not only stronger, but safer partitions. In modern buildings, light-gauge steel structure play a big role because people are keen to fast assembling, economical yet safe buildings. For the steel stud...

-

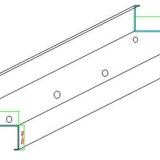

Cable tray rolling forming machine for Hungary

Cable tray rolling forming machine is designed to produce cable trays that are used in different kind of factories and buildings. There are many types of cable trays we can make for you. I will show you some detail information about the machine in the followings. Check a profile and finished pro...

-

Trough cable tray and tray cable tray

The cable trays is divided into a trough type, a tray type, a ladder type, a net format and others. And it is composed of a bracket, a support arm and a mounting attachment. The bridges in the building can be erected independently or attached to various building (construction) structures and pipe...

-

Features of rolling shutter door

The rolling shutter door body is made of high-quality stainless steel and other materials. It adopts the principle of parallelogram and is flexible. The drive is driven by a special motor, the worm and worm gear are decelerated, and a manual clutch is provided. When the power is off, it can be ma...

-

Guardrail roll forming machine

Guardrails roll forming machine is one of most popular roll forming machines, two wave or three wave guardrails are optional. Different countries have different standards of highway guardrails, we design the guardrail forming machine according to customer’s profile drawing. Two guardrails and th...

-

Hydraulic uncoiler with a car

The hydraulic uncoiler is a special equipment for the roll forming machine, and the movement shaft can be expanded and contracted in the radial direction. A rotary oil cylinder is connected to the end of the reel shaft, and the cylinder piston rod drives the front end quadrangular axis to axially...

-

Integrated ceiling keel machine

Integrated ceiling keel machine can make light steel keel that is a kind of frame used to support the shape and fixed structure. The keel is the skeleton and substrate of the home decoration. It is very common to use and can be designed according to the buyer's sample or drawings. Some drawing ...

-

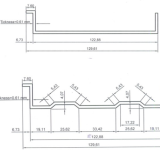

Metal z purlins roll forming machine

Metal z purlins for supporting either roof sheets or vertical wall cladding. Our metal z purlins roll forming machine can produce the accurate manufacture of purlins to virtually any length. This traditional well proven system of sheet support offers a high degree of strength, flexibility and wei...

-

Steel slitting line

Metal sheets or strips suppliers always need slitting machine and cut to length machine line for the production of metal sheets with different widths or lengths from GI, PPGI or stainless coils in large quantities. A steel mill most of time produces only wide steel coils, and steel or metal fabri...

-

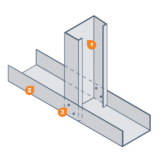

Pallet rack upright frame roll forming machine

The pallet rack upright frame roll forming machine is a "Turn-key" production line for manufacture upright columns with slotted assemble holes for the support on the rack shelving system. It is made from middle gauge steel thickness from 1.2-2 mm. The slotted holes are for the assemble and reset...

-

Roller shutter door roll forming machine

The roller shutter door slat roll forming machine is a simple and flexible production line manufacture of various kinds of metal shutter slat profile for metal door industry. The roller shutter door slat roll forming machine is available to produce different kinds of roller shutter slat profil...

-

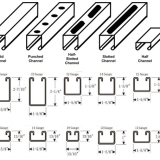

Strut channel roll forming machine

The strut channel roll forming machine is a high performance production line for manufacture various sizes of channel profile. It is made from light gauge to middle gauge steel. The strut channel is reusable metal profile widely used as pipe support, cable tray support, duct support and solar pan...

-

Omega roll forming machine

Omega roll forming machine is for making omega channel in batch, in ceiling and drywall making. Omega channel is the weight bearing channel, so normally we will design with dotting. This device uses a high level of color steel automatic control software, production information management. The en...

-

Light steel keel roll forming machine

Light steel keel roll forming machine can make many drawing profiles according to your requirements. Wall thickness of the product out of the apparatus can be made very thin, but also greatly simplifies the production process, improve production efficiency. Check some drawing profile Features...

-

Quick adjustment CZ steel profile roll forming machine

The C & Z steel profile formed by this CZ steel profile roll forming machine have outstanding anti-bending property and are easy to install. They are widely used as the supporter wall in factory, warehouse. In addition, multiple profiles can be produced through quick adjustment. In the follow...

-

What is the c purlin machine

C purlin is automatically formed by c purlin machine. The c purlin machine can automatically complete the forming process of C purlin according to the given C purlin size or drawing profile. The C purlin machine is a single roll forming unit that can produce a variety of C purlins. The machi...

-

Half automatic interchangable CZ purlin machine

The half automatic interchangable CZ purlin machine can produce various specifications of CZ purlins by half automatic simple stepless adjustment using the same set of equipment. It is not necessary to change the forming rolls when changing specifications. The production process adopts automatic ...

-

C stud roll forming machine

Thin sheets of galvanized steel can be cold formed into c studs for use as a structural or non structural building material for both external and partition walls in both residential, commercial and industrial construction projects. It is popular in modern building because light weight, recyclable...

-

Metal stud roll forming machine

Metal stud roll forming machines are the main type of machine for producing these steel framing studs. Also called stud and track rolling machines, a roll forming machine can run at high speed and produce as much metal studs as is required. Studs are shaped little by little as they mo...

-

60X27 stud and 27X28 track roll forming machine

In modern society, c stud and u track are mainly used for false ceiling making and drywall making. CU keel systems are easy to handle, economical, non-combustible, high quality alternate to more traditional framing materials such as wood. Non-load bearing steel framing includes: steel studs and t...